K-Cup & Nespresso Coffee Capsule Filling Sealing Packaging Machine: Compatible Coffee Pod Filler Sealer

Purchase your Nespresso and K-Cup compatible coffee capsule filling and sealing machine online. We offer the top single-serve coffee packaging equipment suitable for both small batch and mass production.

1 year Warranty

1 year Warranty

Free Shipping

Free Shipping

Secure Payment

Secure Payment

#1 Cost-Effective

#1 Cost-Effective

- US$427

- Labor-saving design

- Up to 400 Pcs/Hour

- Free worldwide shipping

- 1-year warranty

- Best for small batch production

- US$397

- Labor-saving design

- Up to 400 Pcs/Hour

- Free worldwide shipping

- 1-year warranty

- Best for small batch production

- US$9,399

- Suits for K-cup/Nespresso/Dolce Gusto

- 2,400 Pcs/Hour

- Free worldwide shipping

- 1-year warranty

- Best for mass production

- Food grade PP

- Compatible for all K-Cup brewers

- Free worldwide shipping

- Best price

- Food grade PP

- Compatible for all Nespresso brewers

- Free worldwide shipping

- Best price

- Food grade PP cups

- Custom logo service available

- Free worldwide shipping

- Best price

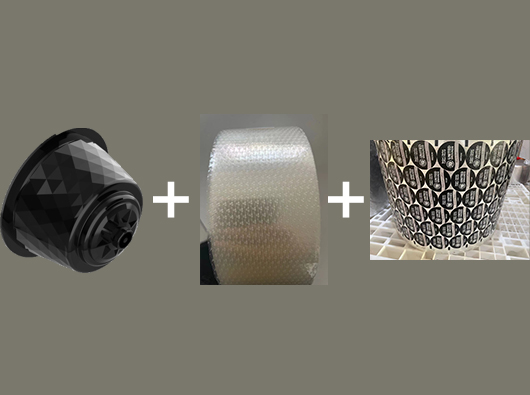

One-stop solution for coffee capsule packaging

We’ve got coffee capsule filling machines for the most popular brands out there! Our selection of single-serve cup packing equipment gives you plenty of options to pick from. With our manual sealer or fully automatic machine, along with empty coffee capsules from A&H Machinery, you can easily produce your own single-serve coffee cups compatible with K-Cup, Nespresso, Dolce Gusto, Lavazza, or other capsule coffee brewers.

A&H machinery One-stop solution for k-cup packaging

We offer both fully automatic K-Cup filling and sealing machines, as well as manual K-Cup sealing machines for your selection. Plus, we provide a comprehensive one-stop solution for both options! As a leading supplier of K-Cup sealers and K-Cup pod fillers, our reach extends across the United States (USA), Europe, and numerous other countries.

We provide a complete one-stop service for single-serve coffee production. We’ve assisted customers worldwide in launching their K-Cup pod manufacturing ventures. Everything you need to enter the Keurig-compatible K-Cup market is right here, including K-Cup packaging consumables (such as empty K-Cups and K-Cup foil lids) and K-Cup packaging machines. Did you know how many K-Cups are sold each year? With such a staggering number, it’s clear that the future of compatible K-Cups is promising! With our K-Cup manufacturing machine, producing your own K-Cups is a breeze. So why wait? Join us today!

A&H machinery One-stop solution for Nespresso compatible capsule packaging

We offer a choice between our fully automatic Nespresso capsule filling and sealing machine and a manual Nespresso capsule sealing machine. Additionally, we provide a comprehensive one-stop solution for Nespresso capsule production!

Opting for our manual machine entails using a Nespresso pod filler (which we provide for free) to fill coffee powder into empty Nespresso capsules, followed by sealing the capsule with foil lids using a manual sealer. On the other hand, our fully automatic machine handles the filling and sealing process automatically, eliminating the need for manual intervention.

Furthermore, our coffee pod manufacturing machine can be tailored to accommodate other brands of coffee capsules. Simply send us a sample of your capsule, and we’ll devise a solution for you.

Customized packing solution

If you’re in need of machines to pack other compatible coffee capsule brands, or even non-coffee capsule cups, just reach out to us. We’ll tailor a customized solution to meet your specific needs.

Contact Us

We are here to help

About Us

A&H Machinery is your go-to source for cutting-edge machinery tailored to crafting compatible coffee capsules for top brands like K-Cup, Nespresso, Dolce Gusto, Lavazza, and more. Whether you’re a small-scale artisan or a mass producer, our range of equipment guarantees precision, reliability, and unparalleled quality. Join us in revolutionizing your coffee capsule production journey today!

Our commitment to excellence extends beyond our products. We prioritize customer satisfaction, offering unparalleled support and expertise every step of the way. From initial consultation to installation, training, and ongoing maintenance, we’re here to ensure your success in the competitive coffee market.

Work Space

Machine Technical parameters:

Voltage:110V/220V, 50/60HZ

Power:2.5KW

Filling head:1

Production capacity:3000 Cups per hour

Total weight: About 900kg.

Measurement: 150*134*200cm

The degree of the automation:Fully automatic

Supported cup style:K-Cup,Nespresso,Dolce Gusto,Lavazza,etc

| Power | 110V/220V, 50/60HZ,460W |

| After sales | Lifetime support, 1year warranty |

| Process Way | Intelligent Heat sealing |

| Process time | 1.5s |

| Temperature adjustable | 0~400℃ |

| Support coffee capsule brands | K-cup,Nespresso |

| Payment term | Paypal |

| Delivery time | 10-15 days, door to door shipping via FedEx or DHL |

The machine is designed with an Italian-inspired concept.

Nespresso Compatible: Our products enable you to produce coffee capsules that are compatible with Nespresso machines.

K-Cup Compatible: Utilizing our supplies, you can create coffee capsules that are compatible with Keurig K-Cup brewers.

| AHL-2 filling head quantity | 2 |

| AHL-4 filling head quantity | 4 |

| AHL-6 filling head quantity | 6 |

| AHL-2 Capacity | 6,000pcs/hour |

| AHL-4 Capacity | 12,000pcs/hour |

| AHL-6 Capacity | 18,000pcs/hour |

| AHL-2 Power | 220V/110v 50/60Hz 4kW |

| AHL-4 Power | 220V/110v 50/60Hz 5kW |

| AHL-6 Power | 220V/110v 50/60Hz 6kW |

| AHL-2 Dimension | 2,800*1,500*2,100MM |

| AHL-4 Dimension | 3,500*1,500*2,100MM |

| AHL-6 Dimension | 3,500*1,500*2,100MM |

| AHL-2 Gross Weight | 1,100kg |

| AHL-4 Gross Weight | 1,400kg |

| AHL-6 Gross Weight | 1,600kg |

| Model | AHD-2 | |

| Filling head | 2 | |

| Capacity | Dolce Gusto | 4000-4800 capsules per hour |

| Filling volume | 1-30 grams (adjustable) | |

| Accuracy | +/- 0.05-0.1 gram | |

| Power | 3 KW | |

| Air | 0.7 m3/min | |

| Power source | 220V/380V/50HZ/60HZ 3PHASES, L3+N+PE | |

| Weight | 1200 KG | |

| Dimension | 3300*1500*2000 MM, L*W*H | |

How to Choose a Coffee Capsule Packaging Machine Supplier

The booming demand for single-serve coffee, especially in capsule format (like Nespresso®, Dolce Gusto®, and K-Cup®), has created a rapidly growing market for coffee capsule packaging solutions. Whether you’re launching a new coffee capsule brand or upgrading your existing production line, choosing the right coffee capsule packaging machine supplier is a crucial business decision.

Here’s a step-by-step guide to help you select a supplier who can meet your needs in terms of quality, reliability, and long-term value

- Before approaching any supplier, clearly define:

- Production volume (capsules per minute/hour/day)

- Capsule type (e.g., Nespresso®, K-Cup®, Dolce Gusto®, Lavazza®)

- Packaging materials (plastic, aluminum, compostable)

- Sealing method (heat seal, ultrasonic, etc.)

- Automation level (semi-automatic or fully automatic)

- Budget and space constraints

A supplier who understands your product vision will be more capable of recommending the right machine configuration.

- A reliable supplier should provide robust technical specifications and customization options. Look for:

- Precision and speed of the filling and sealing process

- Compatibility with various capsule types and materials

- Hygiene and food safety standards

- Ease of integration with upstream and downstream equipment (e.g., grinders, nitrogen flushers, cartoners)

- Support for sustainable/compostable packaging

Ask for technical documentation, performance benchmarks, and details on machine construction.

Check the build quality, materials used (e.g., stainless steel), and reputation of the machines. Some indicators of a quality supplier include:

- CE or ISO certifications

- Real-world references or installations

- Long service life and low maintenance needs

- High uptime and consistency

- Warranties and spare parts availability

If possible, request a machine demo or a virtual factory tour.

Top suppliers continuously invest in technology to improve efficiency and adapt to market trends like:

- Compostable capsule sealing

- Nitrogen flushing for freshness

- IoT-enabled monitoring

- Modular designs for scalability

Working with an innovative supplier helps future-proof your investment.

Even the best machine needs reliable support. Look for suppliers that offer:

Installation and commissioning services

- Operator training

- Quick-response technical support (remote or on-site)

- Preventive maintenance programs

- Readily available spare parts

Global or local presence can influence the speed and cost of after-sales service.

Reputable suppliers should be able to provide customer testimonials, case studies, or references in your region or industry. Ask:

Who are their current clients?

Have they worked with similar coffee businesses?

How satisfied are those clients with machine performance and service?

Don’t hesitate to reach out to a few of those clients directly for feedback.

Price is important, but don’t let it be the sole deciding factor. Evaluate:

- Total cost of ownership (TCO), including maintenance, spare parts, and downtime

- Energy consumption

- Expected lifespan of the machine

- Upgrade paths and resale value

Sometimes a slightly more expensive machine offers greater ROI in the long run.

Every coffee business is unique. The supplier should be able to:

- Customize dosing volumes, capsule sizes, or sealing methods

- Integrate branding elements like embossing or custom lids

- Adjust machinery for future growth or product diversification

Customization often translates to competitive advantages on the shelf.

If you plan to sell internationally, make sure the supplier’s machines:

- Comply with FDA (for U.S.) or EFSA (for EU) standards

- Have the proper certifications (e.g., CE, UL)

- Are built with food-grade components and materials

Your machine supplier should be a business partner, not just a vendor. Choose a company that:

- Offers a consultative approach

- Is financially stable and has a strong industry reputation

- Demonstrates interest in your long-term success

Final Thoughts

Choosing a coffee capsule packaging machine supplier is not a decision to rush. The right supplier can streamline your production, elevate your brand, and drive business growth. Take the time to research, ask the right questions, and prioritize quality, service, and reliability over short-term savings.

With the right partner, your coffee capsule business can thrive in a competitive market fueled by convenience, consistency, and innovation.